A U.S. territory since 1898, the island of Guam is home to approximately 170,000 residents, including 12,000 U.S. military members and their families. To meet the needs of recent population growth in the island’s northern district, as well as the upcoming relocation of 5,000 deployed U.S. Marines from Japan to Guam’s new military base, Guam Waterworks Authority (GWA) needed to restore aging sewer infrastructure. Working as a sub-consultant to joint-venture Core Tech-Hawaiian Dredging Construction Company (CT-HD) and local engineering firm Duenas, Camacho and Associates (DCA) as part of a progressive design-build effort funded by the U.S. Department of Defense (DoD), Gresham Smith overcame Guam’s remote location and tropical climate, as well as a tight schedule, to engineer trenchless improvements to approximately 45,000 linear feet – over eight miles – of large diameter gravity interceptor sewer line.

linear feet of sewer

manholes repaired

gallons of potable water saved

Pinpointing the Problem

The existing sewer infrastructure that serves the northern part of Guam, including Andersen Air Force Base (AAFB) and Finegayan, conveys wastewater to the Northern District Wastewater Treatment Plant. Constructed of Techite Reinforced Polymer Mortar Pipe and Asbestos Cement Pipe, both of which are known to have performance issues, the system was experiencing failures and blockages that were causing groundwater infiltration and inflow and ultimately compromising the integrity of the sewer line. Beginning in 2018, the Gresham Smith team used a topographic survey of the project area, geographic information system (GIS) data, closed-circuit television video and software-generated reports to pinpoint the problem and begin the design process.Overcoming the Climate With UV CIPP

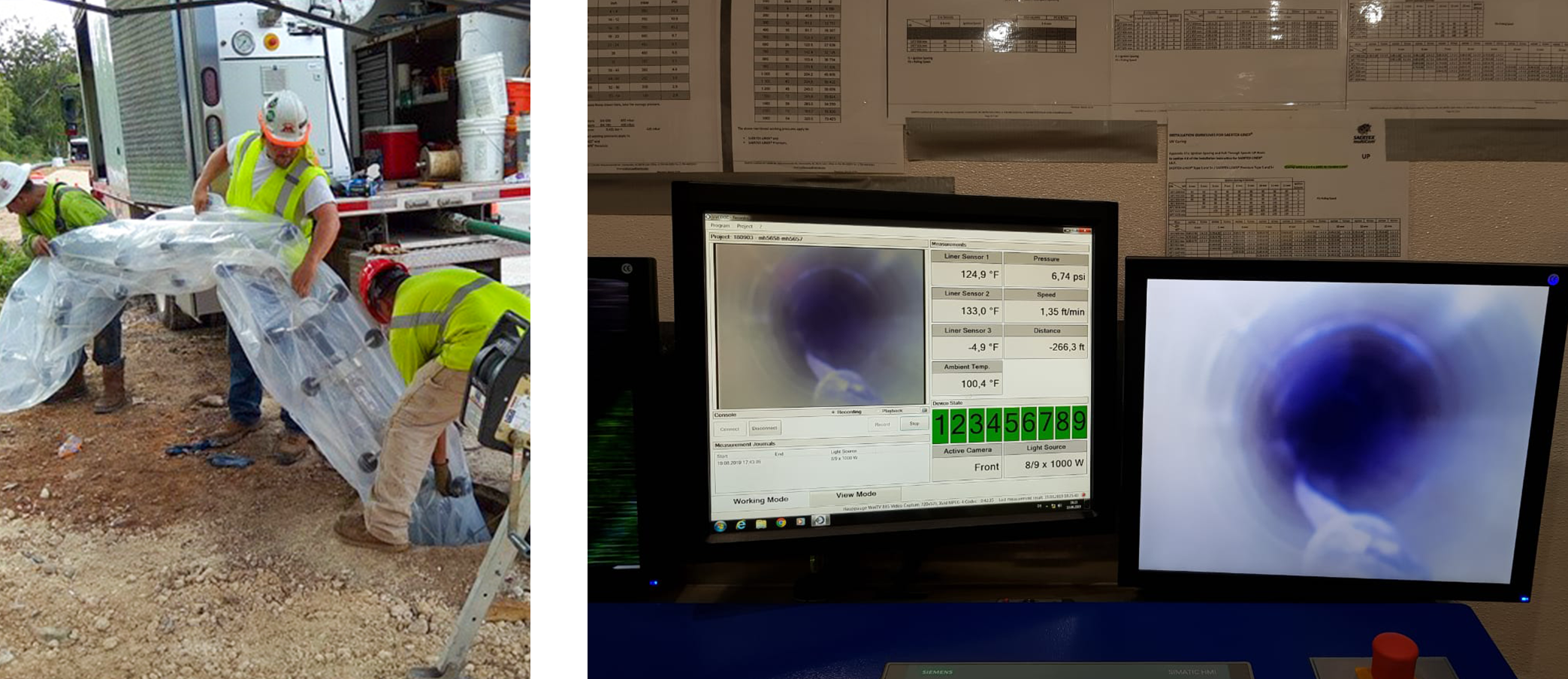

GWA initially intended for the project to utilize conventional cured-in-place pipe (CIPP) for the sewer rehabilitation, but the island’s high heat and humidity prematurely activated the curing agent in the resin. Gresham Smith and the design-build team proposed an alternative technology—ultraviolet light cured-in-place pipe (UV CIPP). A less widely used method, UV CIPP involves pulling a glass reinforced plastic liner impregnated with resin into place in the existing sewer and inflating it with air before using a UV light train to cure the resin and form the cured-in-place pipe.Since the liners couldn’t be impregnated on the island due to the remote location, they were stored in refrigerated, light-tight containers, and transported 15,000 nautical miles by container ship from Germany to Guam. Once on the island, the team had to keep the liners liner at a constant 60 to 70 degrees Fahrenheit—much cooler than Guam’s average temperature of 90 degrees Fahrenheit—and utilized a cold storage facility until each piece was ready to be installed.

The final design solution included epoxy coating the interior of 140 manholes and rehabilitating eight miles of 18- to 42-inch sewer lines using UV CIPP to restore the structural integrity of the sewer system, maintaining conveyance and protecting Guam’s groundwater supply.

Location, Location, Location

The project’s location on the island also proved challenging. The project required substantial bypass pumping during the rehabilitation, but portions of the interceptor sewer traverse residential neighborhoods, a resort, and a narrow, curvy right of way. The project team configured the 17 bypass pumping set ups, each of which bypassed nearly half a mile of interceptor sewer, to reduce lane closures and interruptions to traffic flow and coordinated with a major highway project happening concurrently on the island to minimize disruption to residents and tourists.The interceptor sewer also crosses through two large sections of jungle terrain, and the team had to steer clear of Guam’s overpopulated species of brown tree snakes, numbering around 2 million with densities of up to 13,000 per square mile. The team also had to protect the habitat of the Mariana Common Moorhen, an endangered species, and avoid disrupting Chamorro ancestral lands.

Protecting Potable Water

There are only two main sources of freshwater on the island of Guam: surface water from rivers and reservoirs on the south half of the island, and groundwater from the Northern Guam Lens Aquifer in the north. The island’s hot, humid climate means that up to 50% of total annual rainfall returns to the atmosphere by evaporation and transpiration and does not recharge the aquifer, making water one of the most important resources for keeping Guam’s communities healthy and thriving. By using UV CIPP on this project, GWA saved approximately 1.9 million gallons of potable water, while also minimizing the amount of pollutants released into the environment during the curing process.Ahead of Schedule, Under Budget

Scheduled to complete in September 2020, Gresham Smith and the design-build team finished the project three months ahead of schedule and met the strict timeline required by the Department of Defense grant. Additionally, the team executed the project under the anticipated budget, saving DWA nearly $140,000.The rehabilitated large diameter interceptor sewer provides a long-term solution for GWA, extending its useful life for at least 50 more years and reducing capital and maintenance costs. Guam’s wastewater infrastructure will be suited to support strategic military bases and accommodate Guam’s expected population for decades to come.

Project Contact

Our team develops creative solutions for the world's toughest infrastructure problems.

Learn more about our Engineering expertise.