Bordered on the north by the Tennessee/Mississippi state line, DeSoto County, Mississippi, has experienced tremendous growth over the past two decades. With nearby central Memphis losing residents at an unprecedented rate, DeSoto County suburbs such as Southaven and Olive Branch have been absorbing these migrating citizens.

In an effort to attract an estimated 47,000 northern Mississippi residents who travel across the state line to receive healthcare services, Memphis-based Methodist Le Bonheur Healthcare (MLH) elected to build a 100-bed, full-service, faith-based hospital in the growing city of Olive Branch.

bed, full-service hospital

budget met through target value design

energy savings from geothermal heat pumps

Team Members as Equal Partners

With the vision of creating a sustainable, state-of-the-art facility for $100 million, MLH chose to implement an integrated project delivery (IPD) model to maximize its limited budget. As part of a unified team, Gresham Smith, Smith Seckman Reid (SSR) and Turner Construction Company were selected to design and build the new hospital. The innovative tri-party agreement would require the collaboration of all team members as equal partners, reinventing the traditional owner/architect/contractor relationship.

Methodist needed a 100-bed hospital and had $100 million to do the total project. That wasn’t just the construction budget—that included medical equipment, furniture and everything else that was going into the project. So we used an IPD tool called component team pricing, sometimes referred to as target value design. In short, we took the construction portion of the project and broke it down into smaller components —such as interior, exterior, heating and power budgets—and had weekly meetings with the owner and contractor throughout the design process to track the pricing. If our team discovered that one of the areas was going over budget, we were able to take actions to pull it back in, making sure the tight budget stayed on track.

The use of building information modeling (BIM) also saved project time and ultimately money by facilitating clash detection prior to the official release of documents. The implementation of this process—which enables the effective identification, inspection and reporting of interferences in a 3-D project model—allowed all building systems to be seen, analyzed and coordinated prior to working in the field, and enabled multiple disciplines to work together simultaneously.

A Commitment to Sustainability

Along with adhering to the limited budget, another key objective of the project team was to design an energy-efficient hospital that reflected Methodist Healthcare’s commitment to sustainability. In order to meet the energy-use goals of the client, we implemented energy-saving strategies such as the use of LED lighting; dynamic, photoelectric glass; and leading-edge geothermal heat pumps.

Our team installed geothermal heat pumps—186—throughout the building, including one in each patient’s room. The pumps take advantage of the natural heat sink of the earth with geothermal wells that regulate the source water’s temperature. Utilizing the innovative system throughout the facility is projected to return an annual energy savings of 25 percent, with a five-year return on investment.

Another pioneering decision made by MLH was to glaze the hospital’s two-story lobby with dynamic, photoelectric glass, making Methodist Olive Branch Hospital the first building in the United States to use this revolutionary type of glazing. The glass electronically dims at certain set points and has the ability to transition from a clear to a variable tint at the touch of a button, so it gives operators the ability to reduce glare and solar gain.

Room to Grow

With growth patterns for small, greenfield hospitals often difficult to predict, Methodist Healthcare challenged the project team to design a hospital that would easily adapt to the ever-changing nature of healthcare. To achieve this, the Gresham Smith team employed a design solution that not only gives the new facility room to expand, but also provides it with remarkable flexibility.

Patient areas and clinical spaces were designed to have dual purposes, serving as overflow areas that will reduce wait times and improve the overall patient experience. Additionally, the connection of the hospital’s two main entrances will allow for overflow seating and promote simple wayfinding. On the surgical floor, a centralized prep and recovery area for outpatients of the surgery, cath lab and endoscopy departments consolidates space and maximizes efficiency. Also enhancing flexibility, the size of the central nurse station was dramatically reduced due to the incorporation of smaller, decentralized work alcoves (located outside each patient room) that enhance the nursing staff’s interaction with patients.

Working with the Site

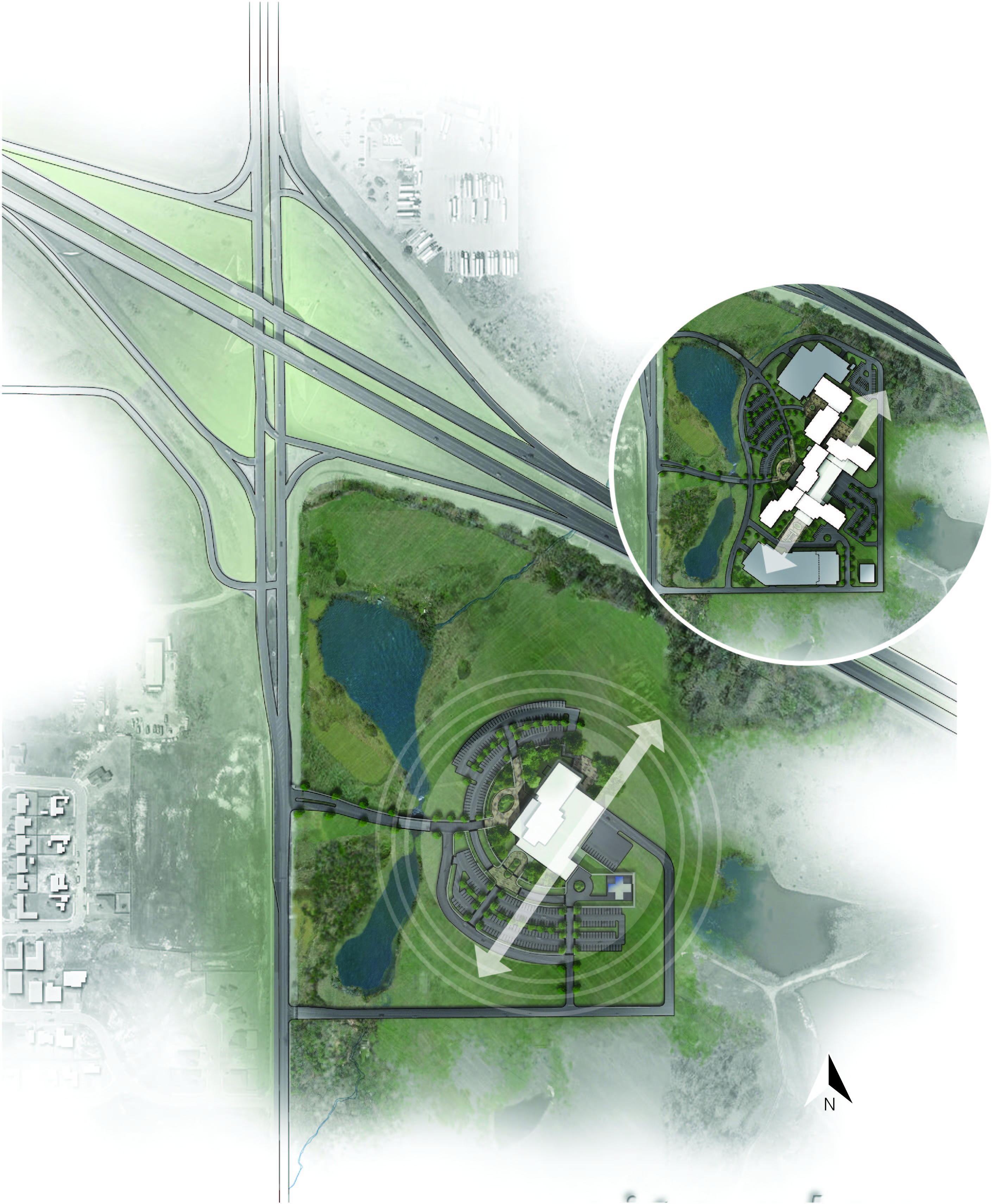

While the location selected for the new hospital contained more than enough total area for the current program and future expansion, closer investigation revealed two wetlands and a protected blue-line stream that traversed the 40-acre site. These unexpected site limitations were to have an enormous impact on the design of the building, affecting its location, orientation, façade and landscaping strategy.

Our team decided that the best option was to rotate the building so the hospital’s growth patterns could maximize the land they had. The small amount of tilt also took advantage of solar orientation and natural views. With the building’s location and orientation established, design elements representing Methodist Healthcare’s commitment to spiritual outreach were incorporated into the hospital’s arrival sequence and landscaping.

Representing the future of healthcare in the region, the new faith-based, patient- and family-centered hospital will allow Methodist Le Bonheur Healthcare to provide high quality, cost-effective care to the thousands of residents it already serves in its Memphis-based facilities.

Project Contact

Our team develops creative solutions for the world's toughest infrastructure problems.

Learn more about our Engineering expertise.