The global battery manufacturing industry is undergoing rapid transformation as manufacturers face pressure to adapt to new chemistries that balance performance, cost, and safety. One of the most prominent shifts is the transition from nickel cobalt manganese (NCM) batteries to lithium iron phosphate (LFP).

Why the shift to LFP? While NCM has dominated due to high energy density, LFP batteries are gaining ground thanks to significant cost advantages, enhanced safety profiles, superior durability, and better market fit for mass applications—even with lower energy density.

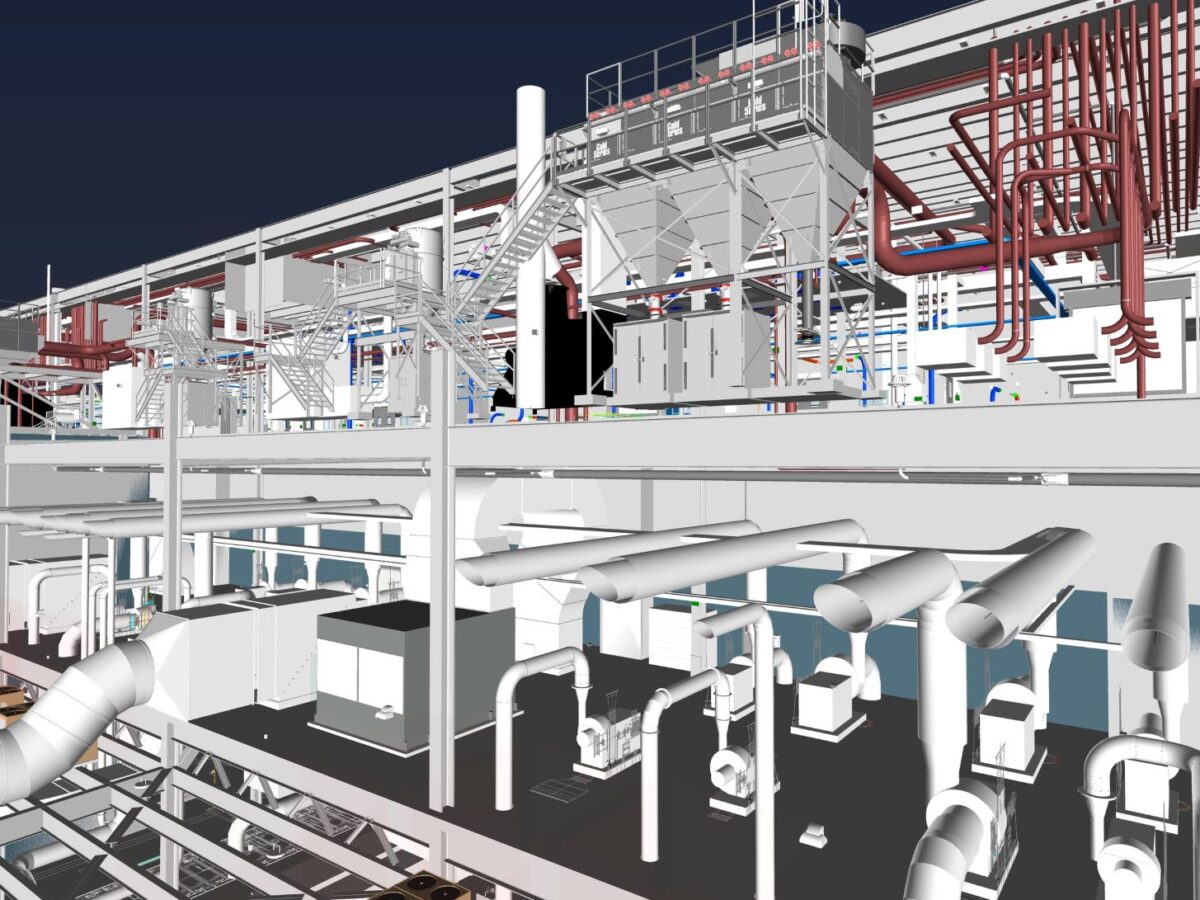

But transitioning isn’t simply a matter of swapping materials. Manufacturers must completely rethink facility design, infrastructure, and operational workflows to accommodate different chemical properties. From process segregation requirements to dual-chemistry facility layouts, the challenges are complex but manageable with the right approach.

What does this mean for your manufacturing strategy? Our industry experts have identified key success factors for dual-chemistry facilities, emerging next-generation chemistries to watch, and critical design considerations that future-proof operations.

Read our complete analysis and implementation guide here, at Battery Technology, including detailed success factors, infrastructure requirements, and insights into the next wave of battery chemistries.