Understand the temperature you’re designing for. Understanding the temperature you’re designing for is also critical. Designing for a 40°Fahrenheit cold storage warehouse that accommodates a cooler is different from designing for a freezer warehouse with temperatures -32°F, as special considerations have to be made to deal with ice. Ice can cause issues around the freezer envelope because it expands as it freezes, can act as an insulator, and of course, it’s hard. For this reason, special consideration needs to be given to removing and preventing ice buildup. Although this is especially important around openings and equipment in a cold storage facility, perhaps the biggest concern lies below the slab in a freezer.

Even the best slab insulation can’t always prevent moisture in the ground -20°F from freezing over time. To keep water from freezing below the slab, the Earth must be warmed to prevent ice from accumulating into a large ice ball known as “frost heaving” (of the soil below), which pushes the slab up. This is typically done via a glycol or an electric heat-trace system within the base slab. Older designs, however, include ventilation tubes with ambient or heated air in the pipes below the slab. The freezer slab must be properly insulated to retain temperature difference between the freezer and the heated slab. It’s important to note that a typical vapor barrier is also needed below the floor slab in a cooler-type space, but it doesn’t have the same insulation or heating requirements.

So, Do:

- Provide a heavy-duty vapor barrier (similar to a pond liner) at a freezer slab.

- Provide proper insulation at freezer slabs. It should be installed in layers, with staggered joints at both the slab and the roof to prevent easy transmittance of temperature.

- Test your glycol system before you pour concrete to make sure there are no holes or punctures in the piping.

- Design redundant loops into the heating system. This way, if one loop goes out, you will still have coverage beneath the slab.

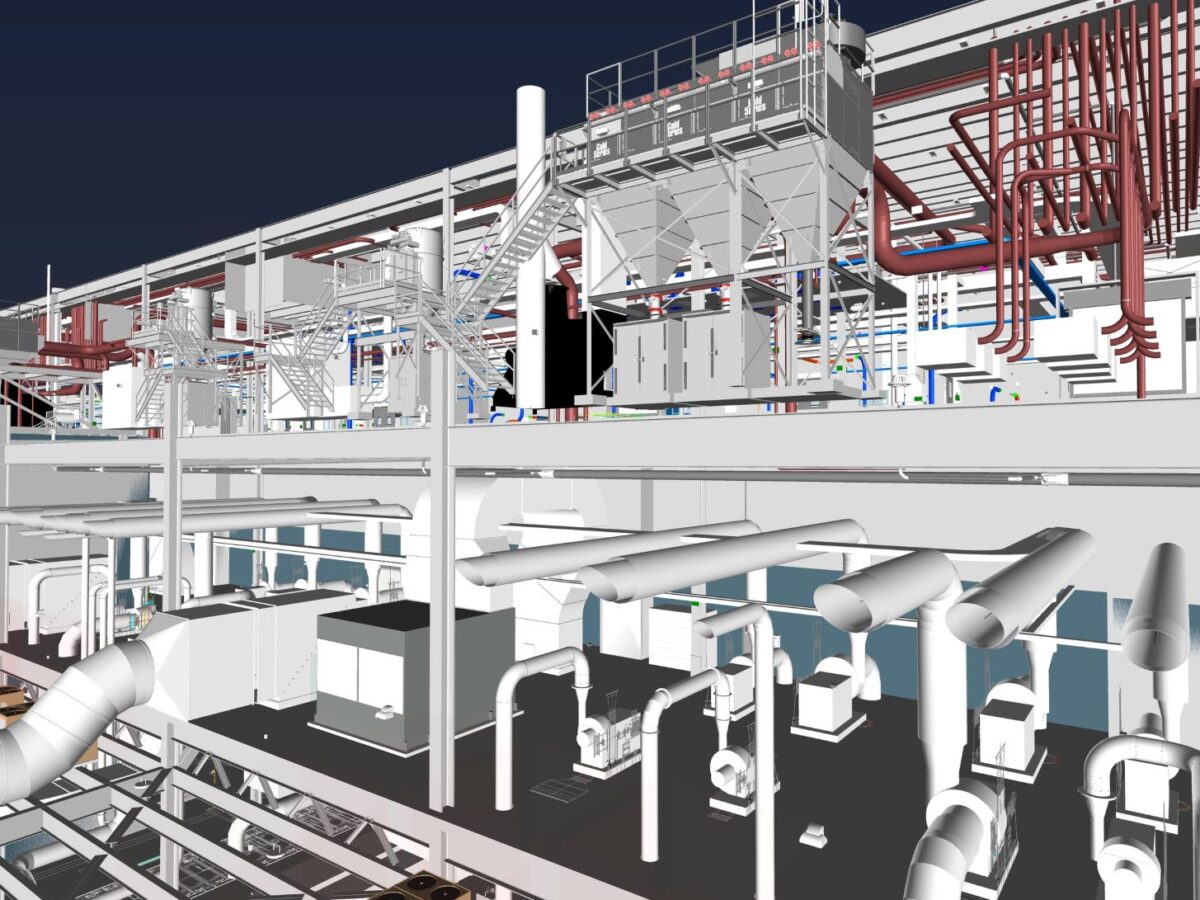

Collaborate. As temperatures vary across the United States, it is important to collaborate with your mechanical engineer to find the appropriate R-value—or thickness of panels—needed for the floor, walls and roof of the building envelope to balance insulation cost vs. energy cost. It’s also important to determine the most appropriate refrigeration system with your refrigeration design experts. This should be done early in the design process to help guide the most efficient building design and to allow for space requirements and constraints. It also facilitates a better understanding of required penetrations into the building envelope to support the refrigeration process.

Consider insulation and envelope terminations. A best practice is to use insulated metal panels (IMPs) for the building envelope and to provide continuous insulation at all transitions. This means that thermal breaks need to be provided at transitions between the slab, wall and roof insulation. It’s also important to consider all envelope terminations and transitions between materials, and to ensure that the vapor barrier is continuous. Without assuring a vapor-tight envelope with insulation-to-insulation conditions, you will have a buildup of ice and a failure in the space.

Understand the effects of temperature. It’s imperative to understand building materials and how temperature affects them. When metal penetrates spaces of different temperatures, it will transmit temperature. For example, a steel beam will transfer cold to warm. A freezer structure, however, is a completely separate and independent structure from the adjacent warmer space, so there isn’t the transfer of temperature across the structure. A big “do” is to galvanize structural steel. Without this protection, the steel will rust over time due to the atmospheric conditions.

Allow for time to bring down the temperature. You don’t build a freezer and just turn it on. You have to bring down the temperature in the surrounding space in increments to slowly climatize the environment to the different temperature. Keep in mind that getting a space to full 0° is a slow transition that can often take up to a month. So, it’s important to build that time into the schedule.

Understand the racking and retrieval system. Racking and retrieval systems in cold storage facilities can be manual, but these days, are more likely to be automated in a large warehouse, which involves cranes and retrieval components. Therefore, it’s key to clearly understand how the owner intends to use the racking and retrieval system within the facility, as developing the most efficient design can vary depending on the needs of the client.

Use foam-in-place insulation. As you’re making the various transitions, it’s often hard to find board insulation that gets into all the “nooks and crannies.” That’s why it’s important to use foam-in-place insulation at transitions between the wall and roof to maintain a continuous thermal envelope. Another acceptable option is to provide neoprene insulation inserts at deck flutes to minimize any thermal transfer at the roof deck/interior partition connection.

Pay attention. It’s a “do” that bears repeating. Pay close attention to every little opening and penetration. Materials have to be insulated, elements have to be heat-traced and penetrations need to be properly insulated and sealed to maintain continuous insulation and a vapor-tight envelope. This includes sealant applied in the insulated panel joint as well as the surface joints. And, speaking of joints, always provide joint sealants in the floor slab control and expansion joints that can be installed and kept at colder temperatures. Only install the sealant once the space is down to the final temperature to ensure the full joint is filled due to contraction of the floor slab.

Some important don’ts:

- Don’t forget to analyze heat transfer when building adjacent to an existing freezer or cold storage. If there are varying floor heights, heat transfer from adjacent structures needs to be considered. Heat trace or glycol warming may be required in vertical transitions such as concrete stem walls.

- There are different ways you can specify how roof insulation gets installed. One thing you don’t want to do is create thermal bridging with roof insulation fasteners. If you are working in an area that requires fastening through the insulation due to wind uplift requirements, stainless-steel fasteners should be specified to reduce the risk of corrosion.

- Because you don’t need to get super fancy with design features for a cold storage facility, avoid parapet conditions at cold storage areas due to thermal transfer. It’s always best to keep transitions and terminations of insulation, vapor barriers and panels simple and clean for easier installation.

- Don’t stop at design. While the installation of all components is critical to ensuring a vapor-tight envelope that doesn’t create ice buildup inside a freezer, pre-qualification of contractors who have worked on similar project types and sizes is highly recommended. Additionally, pre-installation conferences to outline special requirements and review details is critical. On-site observation and documentation by all parties is also recommended. At the end of the day, it’s inherently easier to execute an installation properly from the get-go than it is to fix something once it’s covered up.

Facilitating a successful delivery

Ultimately, a design team well-versed in the do’s and don’ts of cold storage facility design has the knowledge and experience necessary to focus on even the smallest of details, and that allows a client to fully focus on their logistics and operations for successful delivery to the marketplace.

Jennifer Carr is a Senior Architect with more than 25 years of experience leading project teams toward successful outcomes while prioritizing client objectives. Her experience spans a broad range of corporate, institutional and industrial facilities. Using a comprehensive approach to design, Jennifer offers innovative solutions tailored to each client’s long-term needs, functional goals and operational efficiency.