Industrial

Energy

Interested in learning more about our Industrial expertise?

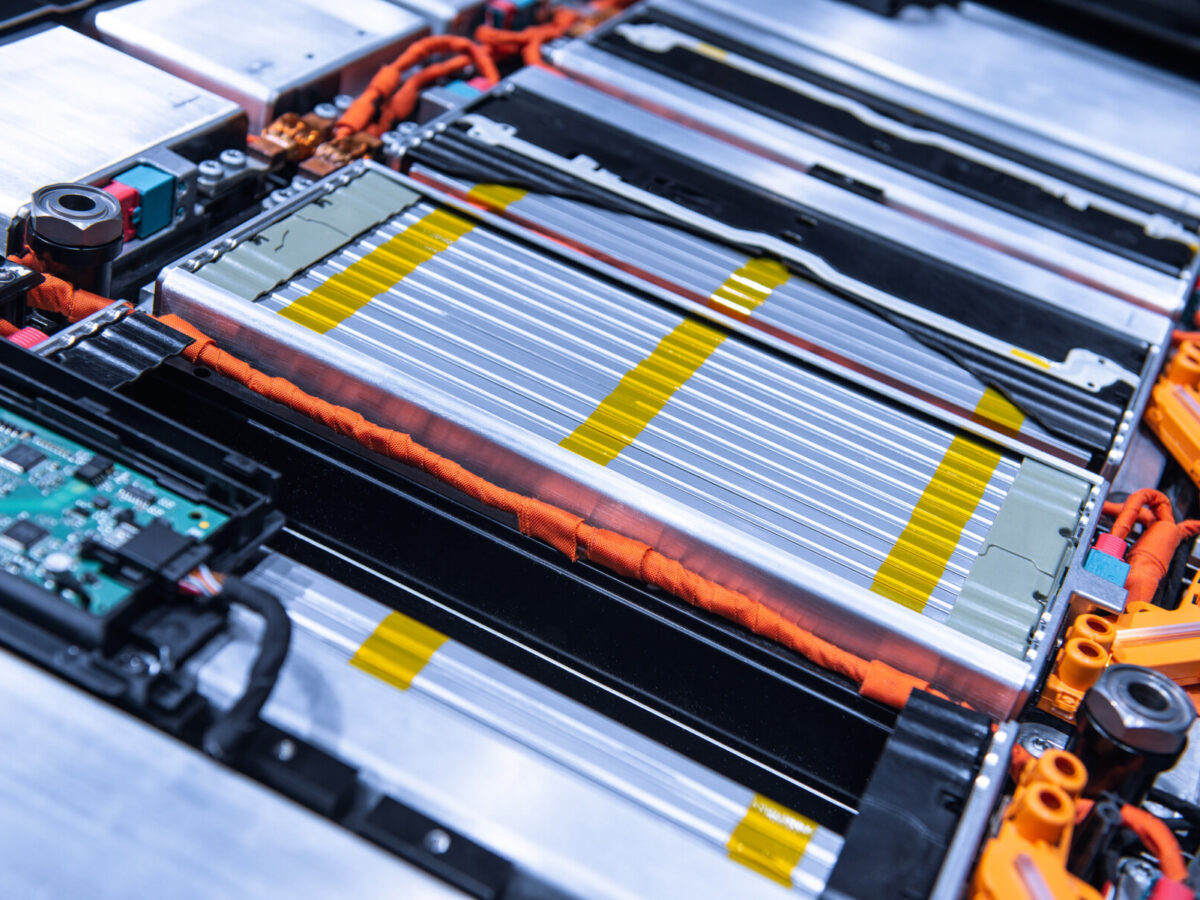

ContactAs the leading design firm for battery plants in North America, Gresham Smith’s extensive portfolio includes collaborations with top-tier battery technology companies like LG Energy Solution, as well as automotive industry leaders such as General Motors, Honda, Hyundai, and Stellantis. We possess comprehensive expertise in the entire battery manufacturing process—from electrode production to cell assembly, formation, module, pack and shipping—and we design facilities that seamlessly support these critical processes.

Our team of experts in dry rooms, clean rooms, and processes recognizes the paramount importance of environment control in production, assembly, and testing areas, given the sensitivity of lithium-ion battery components. We understand the urgency and fluid nature of the battery ecosystem and are well-equipped to adapt quickly to ever-evolving and often demanding market conditions. As a full-service A/E firm with a dedicated utility services team, we offer a spectrum of services, ranging from site evaluation and selection to substation design, construction administration, and commissioning.